Beam Layout Welding Connecticut

The actual production capacity of a steel beam will depend on its size and type, but the typical output is about 2,000 tons per month. This can be achieved in an eight-hour shift by three operators.

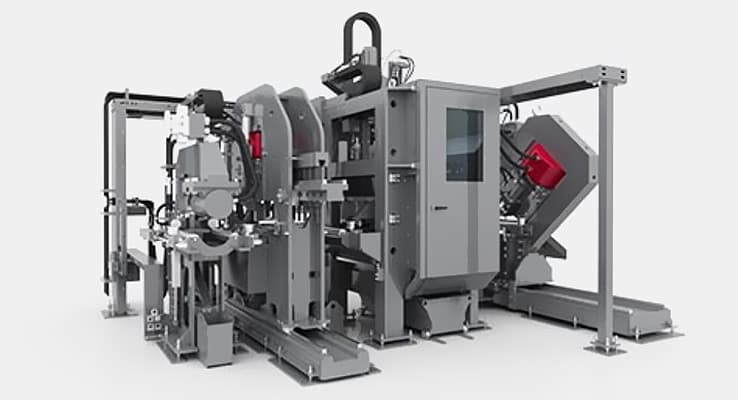

The Beam Layout Welding offers maximum system control flexibility through the Electrical Control Panel. The welder can be used in either Automatic or Manual mode. Manual Mode allows you to control the sequence of the operations using the controls on the control panels. Every welding head controller allows you to customize the parameters of your welding operation.

D3Touch from welding alloys is a touchscreen-based control technology that automates fully automated welding techniques. Welding Alloys incorporates new technology in all Welding Alloys equipment, improving the performance and accuracy of the weld process. This technology compliments our precision engineering mechanics and results in maximum performance.

The actual production capacity of a steel beam will depend on its size and type, but the typical output is about 2,000 tons per month. This can be achieved in an eight-hour shift by three operators.

The solid bed beneath the plate holds the metal plates while the weld head passes through it. This is where the H beam's flanges are made and cut. The web is then made from a length of plate. The web is then loaded onto a conveyor belt, similar to a welding roller, along with the flanges.

To create continuous beam production, the Conveyor System interconnects the Beam Layout Welding with Tacking Fixture, Automatic Welder and Tacking Fixture. Hydraulically controlled, the Conveyors are situated at the entry and exit of Seam Welder Tacking Fixture, Automatic Welder, as well as at the Seam Welder. These controls control the movement, direction and speed of the conveyors adjacent to them.

Once clamps have been released, the web is then transferred to the tacking fixture. The equipment comprises a welding head, flux hopper and travel carriage. Controls are also included. A 1,000 Amp power source is also available. Full-color laser projection systems can project all the information an operator needs in order to accurately tackweld connections on the beam, or any other connections.

The most important part of welding work is the welding arm. It can move horizontally with cross beam and tool carriage. The seam tracking device is installed under welding beam. It has the function automatic tracking which can keep the right distance between welding guns and welding seams.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.